Elon Musk Plans to Build Tesla Chip Fabs Amid Endless TSMC & Samsung Delays

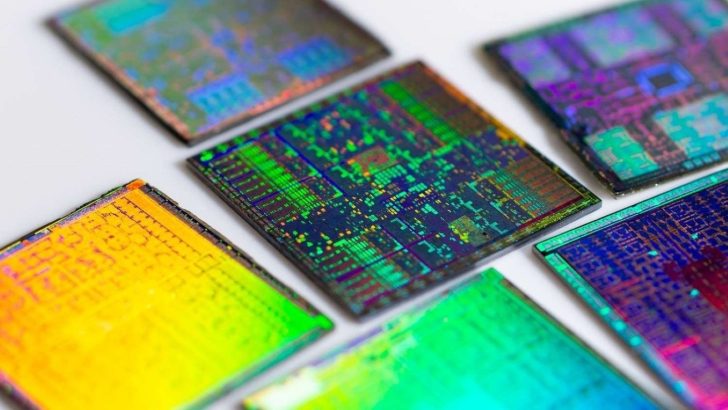

Elon Musk is pushing forward with bold plans to revolutionize the chip supply chain for Tesla, expressing dissatisfaction with the slow timelines set by current suppliers like Samsung and TSMC. Musk envisions a future where Tesla’s chip demand skyrockets, particularly as Full Self-Driving (FSD) technology becomes mainstream. He anticipates needing hundreds of millions of AI chips annually, yet feels that existing suppliers cannot meet these needs swiftly enough.

Elon Musk’s Ambitious Chip Supply Vision

In a conversation with Baron Capital, Musk revealed that Tesla’s chip requirements could reach between “100 million to 200 billion” AI chips per year. However, he criticizes the current suppliers, claiming they demand a “5-year” timeline to establish the necessary production capacity—a timeframe he finds unacceptable. To address this, Musk proposes developing Tesla’s own chip facilities to accelerate production and meet demand within a year or two.

The production speed doesn’t seem fast enough. When I asked them how long it would take from groundbreaking to completion of a new chip factory, they told me it would take five years to start production. I felt that five years was an endless wait for me.

– Elon Musk

This marks the third occasion Musk has mentioned the possibility of Tesla building its own chip facilities. Yet, his plans face significant skepticism. Analysts warn of the financial and logistical challenges, suggesting that even with substantial investment, Tesla might struggle to secure the needed talent and advanced chip technology.

You know, from their standpoint, they’re moving like lightning. I’m just saying that, nonetheless it will be a limiting factor for us. … it might just be that the only way to get to scale at the rate we want to get to scale is to build a really big fab – or be limited in output of Optimus and self-driving cars behind the AI chip supply.

– Elon Musk

Challenges and Alternatives for Tesla’s Chip Supply

As Musk considers a “fab buildout,” critics argue that it could divert significant capital expenditure, and even then, the endeavor could be hampered by a lack of expertise and intellectual property. Some suggest Musk should consider partnering with existing chip giants like TSMC, encouraging them to expand production capacity. TSMC has shown flexibility in the past, even relocating production to the US to support client needs. However, while the concept of a ‘TeraFab’ is appealing, the practicalities of current supply chain constraints might pose insurmountable obstacles for Tesla.